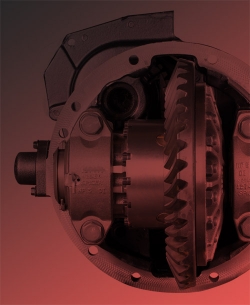

Commercial-Grade Gearing Built to Dana OE Standards

PROBLEM

“I need the replacement gearing in my commercial vehicles to contribute to longer axle life, so downtime is reduced and I save money in the long run.”

SOLUTION

Spicer ring and pinion gearing is made from quality materials and subjected to computer-controlled processes and rigorous testing; it’s proven to outperform non-genuine and non-OE products by as much as 280%.

Genuine Spicer commercial ring gear and pinion sets are designed, manufactured and tested to the same high standards as original equipment (OE) parts—because they are OE parts. When a part is replaced with a genuine Spicer product, you get the same OE performance and reliability you’ve come to expect.

Spicer ring gear and pinion sets are designed and manufactured in matched sets for optimal performance and reduced wear.

Knock-offs simply cannot compete with genuine Spicer quality.

Proven Processes Guarantee Precision

Spicer ring and pinion gearing consistently offers advantages over the knock-offs. That’s because Spicer parts start from quality materials, and then they are subjected to computer-controlled manufacturing processes and rigorous testing.

Spicer ring and pinion gearing consistently offers advantages over the knock-offs. That’s because Spicer parts start from quality materials, and then they are subjected to computer-controlled manufacturing processes and rigorous testing.

- Superior metallurgy

- High-grade steel for maximum durability

- Ensures a more consistent, higher quality product

- Hobbed and shaved gearing

- Provides optimal mating to minimize stress and maximize life

- Precision, premium heat-treating processes and shot-peening

- Reduces residual stress

- Delivers consistent quality, enhanced life and exceptional durability

- Optimum tooth profiles

- Perfect fit between mating gears for extended life and quiet operation

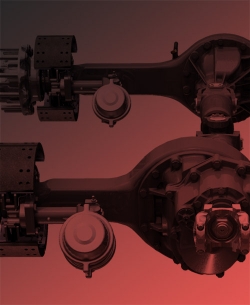

Tested and Proven Quality for Your Commercial Vehicles

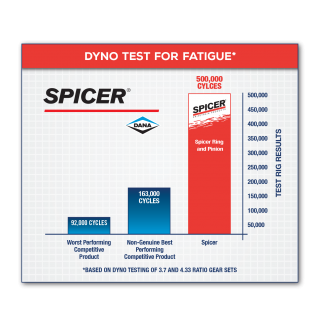

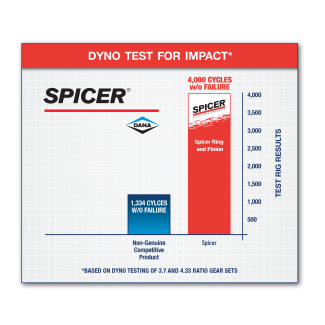

Competitive dyno testing for impact and fatigue shows genuine Spicer gearing outperforms non-genuine and non-OE products by as much as 280%. This translates into longer axle life, saving you money and reducing downtime.

In tests, non-genuine gearing could not be set up correctly,* which will result in increased stress and fatigue, and potentially in premature failure. Spicer gearing offers the benefit of precision-machined gearing for optimal mating to minimize stress. Using a shot-peening process further reduces residual stress and avoids cracking, extending the life of Spicer gearing.

Dana’s precise heat-treating process is tightly controlled and specific to our gearing, and it’s verified by microhardness testing. Alternatively, non-genuine heat treating processes are inconsistent,* leaving steel either too soft or too hard, both of which increase the risk of failures.

| Part Number | Model | Ratio |

|---|---|---|

| 513889 | D170 | 4.10 |

| 513890 | D170 | 4.30 |

| 513384 | DSP40 | 3.36 |

| 513371 | DSP40 | 6.50 |

Reduce your downtime and cost with genuine Spicer ring and pinion gearing. To start enjoying the benefits of Spicer quality, locate your nearest distributor of genuine Spicer gearing for commercial vehicles today.

*Based on samples tested